Enhancing LED Lifetime

LED is defined as the number of operating hours when the brightness of the LED reaches 70% of the original brightness. The operating temperature of the LED is the primary factor in determining the lifetime of the LED. When the LED is operating heat is generated. The overall efficiency of the LED and the brightness of the LED will determine the heat generated by the LED. The operating temperature of the LED can be significantly reduced by properly designing the operating conditions of the LED and by employing advanced methods to extract heat from the LED. Reducing the operating temperature of the LED will significantly improve the lifetime of the LED. Other manufacturers commonly take technical short cuts or don’t understand the need to properly manage the thermal loads generated by the LEDs. This results in a significant reduction in LED lifetime. Litegrafx has a rigorous approach to this technical problem. The illustrations below show the significant differences in the Litegrafx approach versus other manufacturer’s solutions.

Enhancing LED Lifetime

Litegrafx Design Advantages

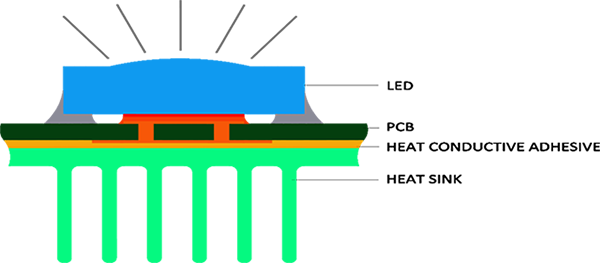

The bottom side of every LED is directly connected to a copper metal pad to rapidly extract heat from the LED.

The copper metal pad is directly connected to a large heat sink pad on the back side of the printed circuit board with multiple solid metal posts. Trying to conduct the heat through the PCB without a direct metal connection will lead to excessive LED temperatures.

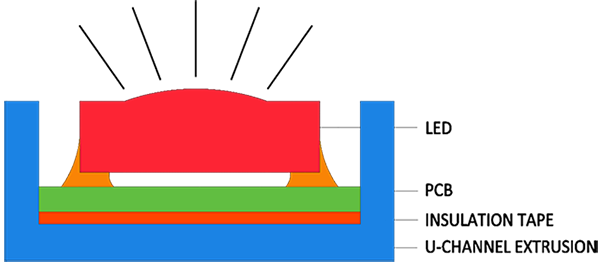

The backside copper pad is attached directly to a custom extruded heatsink using a special thermally conductive adhesive for heat extraction. Other manufacturer’s commonly use double sided insulating tape to attach the PCB to the extrusion which results in increased LED temperatures.

A custom extruded aluminum heat sink with a large surface area is used to insure heat dissipation to the ambient air. Commonly used aluminum U-channel has minimal dissipation area which leads to higher LED temperatures.